In-house manufacturing – Bringing your Dreams to Life

Inspection Of Raw Materials

The first step in selecting materials or goods for production or processing at a facility is to inspect them in Alea Style. The way your kitchen looks and feels is fundamental. The material's quality is also essential. We make sure that every material we pick is water-resistant.

Cutting - Panel Saw/Beam Saw

Alea uses a tech-advanced saw panel to provide manufacturers more control over every machine movement involved in the cutting process.

Pasting - Cold Press/Hot Press

The lay-up stack is pre-pressed at room temperature to guarantee that the plywood panels are strong enough to be automatically handled during hot pressing. The panels are then squeezed between hot press platens to cure the glue. We deploy modern cold pressing techniques for adhesives and production efficiency, which are used to manufacture beautiful kitchen panel cabinets.

Edge bending - Machine

Further, an edge bender binds the edge to the base. The machine trims the trailing edges, flushes the top and bottom edges with the surface, rasps any excess portions, and polishes the completed edge.

CNC - Drilling Routes

A CNC drilling machine digs round holes in the workpiece with a revolving cutting tool. Typically, the holes are drilled to enable machine screws or bolts during assembly.

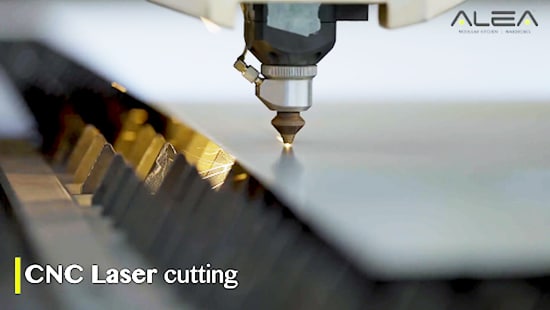

Sheet Cutting- CNC Laser Cutting

The laser beam then melts the material and prepares it for cutting through the infamous vapourization cutting method. A high-pressure gas then removes the prepared sheet.

Sheet Bending - CNC Bending

The giant industrial machines bend sheet metal, from a few millimeters to several meters long.

Powder Coating - Powder Plant

Only color solids in the form of a powder-coated, atomized powder are sprayed onto the product. When the powder is sprayed, it attracts and adheres to the product due to an electrical charge.

Paint/PU Polish - Paint Booth

For high-quality paint finishing, efficient paint booths with overhead mechanical interlocking lines, high-production palletized floors, or low-production batch systems are used.

Assembling

The assembly line process involves adding replaceable components to generate an efficient finished product.

Quality Control

Finally, the goal of the testing is to see if any adjustments to the production process are required. We strive to produce quality-controlled compositions when addressing consumer requests for customized products.

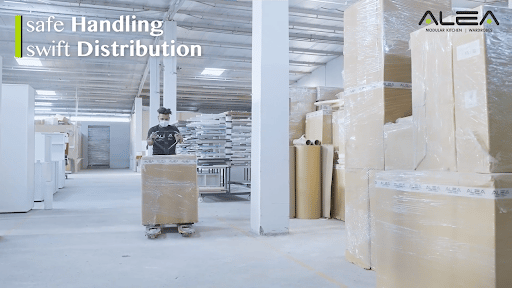

Final Packaging

Once all the elements are manufactured, they are carefully packed and transported to the installation site. Further, our professional installers are all set to do it for you right away.

Using CNC machines, our Raipur Rani production unit creates wardrobes

and modular kitchens through highly skilled managers.

Frequently Asked Questions

Drawers, wire baskets, cutlery trays, tandem drawers, oil extractor carousel for corner cabinets, magic corner. Additionally, you may include Leman's corner tall cabinets with storage baskets to help arrange basic cooking needs such as cereals, pulses, etc.

The following are the components of distinct modular kitchen layouts:

- Base Cabinets: The low cabinet in the kitchen is a base cabinet designed to sit under your worktop.

- Wall Units: Upper modular kitchen cabinets hanging over the counter are wall cabinets.

- Tall Units: Tall cabinets are used to store non-refrigerated foods that are bulky. They are made for storing significant volumes of food neatly and orderly.

- Sink Unit: A kitchen sink unit is a sideboard meant to be used with a sink. There is no back panel on the modular kitchen cabinet design, allowing easy access to plumbing.

- Hob Units: A hob is a heated surface on a cooktop or countertop.

- A thorough understanding of the available space is the first step to buying a modular kitchen in India.

- For a smooth flow, consider the kitchen triangle concept, which views movement between the stove, sink, and refrigerator.

- It is essential to plan out your electrical fixtures carefully, considering the appliances you will need.

- Finally, using professionals for your kitchen interiors makes the most efficient use of available space.

Have More Questions? Contact Us.